The drum in a theory of constraints system… – The drum in a theory of constraints system plays a pivotal role in identifying and resolving constraints, ultimately enhancing production efficiency and overall throughput. This article delves into the concept of the drum, its impact on production schedules, and strategies for effective management within the theory of constraints framework.

Understanding the drum’s significance in a theory of constraints system provides a comprehensive approach to optimizing production processes and maximizing output.

The Drum: Overview and Importance: The Drum In A Theory Of Constraints System…

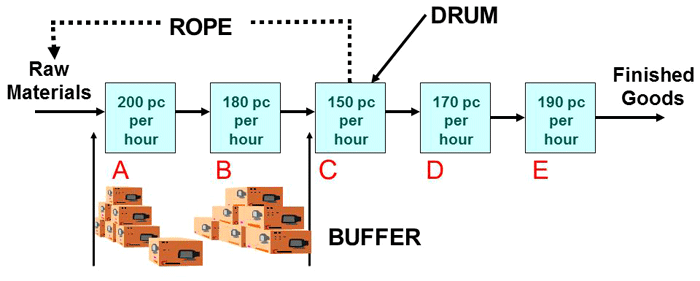

In a theory of constraints (TOC) system, the drum represents the critical resource that limits the overall throughput of a production or service process. Identifying and optimizing the drum is essential for maximizing efficiency and achieving desired outcomes.

The drum acts as the pacemaker for the entire system, setting the production rate and influencing the scheduling of all other resources. By focusing on managing the drum effectively, organizations can identify and resolve constraints, improve production flow, and increase throughput.

Impact on Production and Throughput, The drum in a theory of constraints system…

- The drum determines the maximum production output of the system.

- Optimizing the drum’s utilization rate can significantly increase throughput.

- Bottlenecks at the drum can lead to production delays and reduced efficiency.

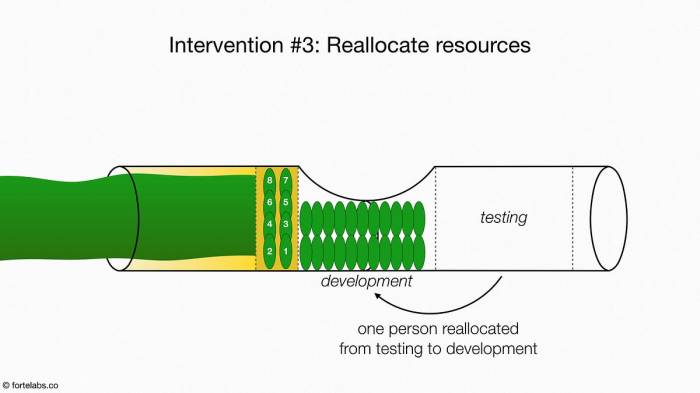

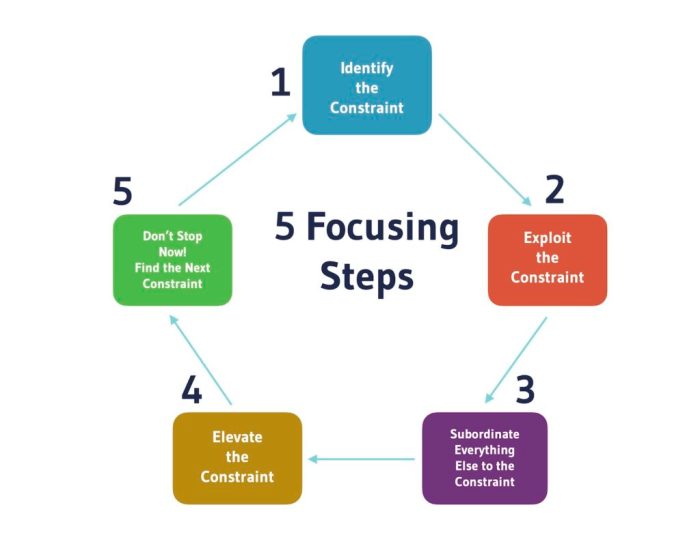

Strategies for Managing the Drum

Effective drum management involves:

- Identifying the true constraint within the system.

- Prioritizing production orders based on their impact on the drum.

- Balancing capacity and demand to avoid overloading or underutilizing the drum.

Integration with Other System Components

The drum interacts with other TOC system components, such as:

- Inventory: Optimizing the drum can reduce inventory levels.

- Customer lead times: Effective drum management can shorten lead times.

Case Studies and Real-World Applications

Case studies demonstrate the benefits of effective drum management:

- A manufacturing company increased throughput by 20% by identifying and optimizing the drum.

- A service provider reduced customer lead times by 30% by focusing on drum management.

Future Trends and Innovations

Emerging technologies and approaches for managing the drum include:

- Artificial intelligence (AI) for constraint identification and optimization.

- Advanced scheduling algorithms to improve drum utilization.

Essential FAQs

What is the primary function of the drum in a theory of constraints system?

The drum serves as the heartbeat of the production system, dictating the pace and rhythm of operations to maximize throughput and minimize waste.

How does optimizing the drum impact production schedules?

Optimizing the drum allows for smoother production schedules, reduced lead times, and improved on-time delivery performance.

What are some key strategies for managing the drum effectively?

Effective drum management involves identifying constraints, balancing capacity and demand, and implementing visual management techniques to monitor and control production flow.